Fundamentals of a Successful Material Handling Weekend Cutover

Michael Thoma | 09 April 2013

For those of you who don’t know, a “cutover” is a rapid transition from one project phase to another, so in the material handling world, it means to quickly transition from your original system--or single piece of equipment--to a new one. Weekend cutovers are becoming more popular as demand for system reliability, increasing throughput, and ever-changing products drive facility managers to find new system solutions, while avoiding the headaches of taking down their current system during business hours.

I have helped in a few material-handling cutovers, so I would like to share my thoughts on how to complete one successfully. Below are a few cutover plan fundamentals:

Being Realistic

Time is your biggest enemy when facing a weekend project. Theoretically, you have from end of business Friday through early Monday morning in which to remove, rework, install, and test your new piece of equipment before it’s needed for production. That’s roughly 62 hours! Some projects might have to be done over several weekends rather than crammed into one. In this case, divide up areas into smaller projects to avoid taking on more work than is possible for one weekend.

Excellent Communication

For a successful cutover, we always keep customers in the loop right from the start and notify them of any schedule or design changes. If you are going through a cutover, make sure your material handling integrator goes over a detailed plan with you, the project team, and any sub-contractors who will be involved. Everyone needs to have a defined role and responsibility in order for the project to be a success. As the weekend work progresses, you should also receive updates from the project manager.

Double Triple Check

Experienced system integrators will fully review cutover plans and have all the necessary supplies ordered and available, so they aren’t stuck trying to find an electrical supply store at 2 a.m. Every hour is vital to a successful weekend cutover. Once you choose an integrator to help with your project, they will likely schedule a kick-off meeting on location. This is highly recommended and will give the team a chance to sit down, explain their plans, and listen to your concerns face-to-face. This also gives them a chance to go on the production floor and obtain any field measurements, pictures, videos, and other notes to help aid in the final design and implementation of your project.

Integration

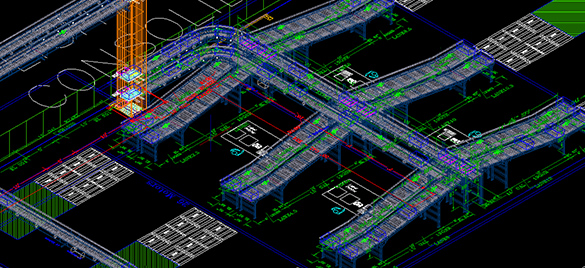

The day has come! It is now time for the project team to lock out the equipment and dive into the changeover. First things first, all contractors, software programmers, and the lead material handling integrators will start with a site introduction meeting. Content of typical site introduction meetings include customer expectations, rules for coming in and out of the building, and a safety course. Once this is complete, they are ready to go.

The project manager or site lead supervisor should make sure equipment is being installed according to plan and specifications. Major REWORK will kill chances of a smooth transition come Monday. The project lead will also need to keep programmers in mind to ensure they have plenty of time to debug the new equipment.

The team should also complete testing before production on Monday. A few minor hiccups can be expected as production volume ramps up, but overall, as long as cutover planning was done well, the project should easily finish on time and to your satisfaction.

Comments

Ron Smith says:

8/28/2018 10:08 AM

I'd add to stress this part of the plan: Receive and inspect the equipment well ahead of time. Often equipment arrives without components or incorrect components. Finding this out early gives more time to correct any deficiencies.

Rick Manning says:

8/28/2018 10:08 AM

Been doing this for forty years. Just didn't have a name for it.

Leave a Reply

Your email address will not be published.

Comment

Thank you for your comment.