Optimizing Warehouse Efficiency through Human-Automation Collaboration

Mebin Scaria | 27 March 2024

In the dynamic landscape of modern warehouses, the integration of automation has changed the way materials are handled by enhancing efficiency, accuracy, and productivity. However, the role of humans remains indispensable, bringing cognitive abilities and adaptability to the table.

Striking the right balance between humans and automation in warehouse material handling is crucial for optimizing operations and maintaining a competitive edge.

Industry 5.0: Transforming Warehouse Operations

Industry 5.0 evolution for manufacturing and logistics, emphasizes human-robot collaboration to achieve optimal outcomes. Unlike Industry 4.0 which solely focuses on robotic automation, it envisions a symbiotic relationship between humans and machines, leveraging the strengths of both. In warehouses, this translates to integrating automation while empowering human workers to oversee, interact with, and complement automated systems.

Automation has significantly transformed warehouse operations, with technologies such as robotic systems, conveyor belts, and autonomous vehicles such as AGVs and AMRs streamlining tasks like picking, sorting, and transporting. These systems offer speed, precision, and consistency, reducing errors and increasing throughput. Advancements in artificial intelligence and machine learning have enabled these systems to continuously improve and adapt to changing demands.

While automation offers undeniable benefits, it cannot fully replace human capabilities. Humans bring critical thinking, problem-solving skills, and emotional intelligence to the warehouse floor. They can handle exceptions, manage complex situations, and collaborate effectively with one another. Human workers possess the flexibility to perform various tasks, making them invaluable assets in dynamic warehouse environments.

Best Practices to Achieve Balance

Augmenting Human Capabilities: Automation frees up human potential by automating repetitive tasks, allowing them to focus on higher-order thinking, problem-solving, and personalized customer interactions. This enriches job satisfaction and elevates safety standards.

Training and Upskilling: It is important to train employees to navigate automated systems, analyse complex data, and work effectively with robots. This will ensure a smooth transition to an automated workplace while also developing a skilled workforce.

Optimizing Human-Robot Interaction: Carefully organize the workflows to make the most of what humans and robots do best. We encourage a collaborative workspace that combines creativity and precision, creating an environment that promotes innovation, efficiency and mutual empowerment.

Workers should feel empowered to provide feedback, suggest improvements and adapt to changes brought about by automation. Likewise, automated systems should be designed with user-friendly interfaces and transparent communication to facilitate interaction with human operators.

Collaboration of Automation and Human Expertise

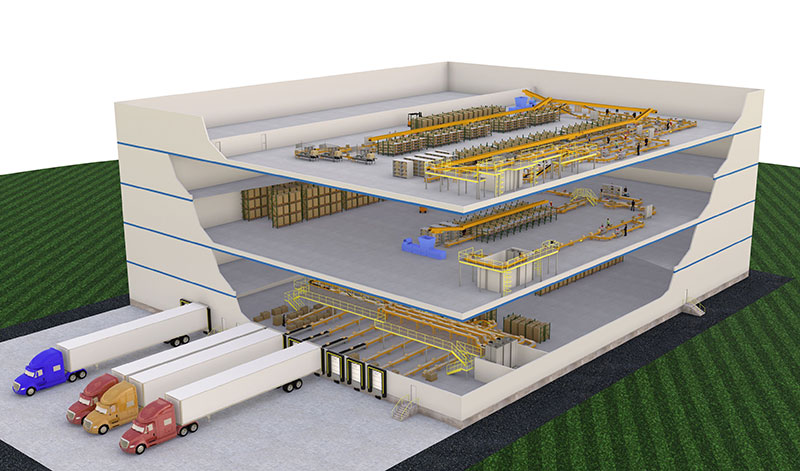

In a modern warehouse, the integration of technologies such as conveyors, Automated Storage and Retrieval Systems (AS/RS), Autonomous Vehicles (AVs) and Collaborative Robots (Cobots) optimizes operational efficiency while fostering collaboration with human workers. Conveyors streamline the movement of goods, transferring them between different areas of the warehouse. ASRS maximizes storage capacity and accelerates order fulfilment by automatically retrieving items when needed. AVs equipped with cobots autonomously transport goods and assist with tasks such as picking and packing, enhancing productivity.

In a modern warehouse, the integration of technologies such as conveyors, Automated Storage and Retrieval Systems (AS/RS), Autonomous Vehicles (AVs) and Collaborative Robots (Cobots) optimizes operational efficiency while fostering collaboration with human workers. Conveyors streamline the movement of goods, transferring them between different areas of the warehouse. ASRS maximizes storage capacity and accelerates order fulfilment by automatically retrieving items when needed. AVs equipped with cobots autonomously transport goods and assist with tasks such as picking and packing, enhancing productivity.

These technologies are seamlessly integrated to create a dynamic warehouse ecosystem. When an order is received, AS/RS locates the required items and delivers them to AVs stationed strategically throughout the facility. AVs navigate autonomously to transport goods to various workstations, where cobots collaborate with human workers to perform tasks efficiently. Human workers oversee operations, focusing on quality control, problem-solving and customer service, while automation handles repetitive tasks and material handling.

This collaborative approach optimizes warehouse processes, improving throughput and accuracy while reducing labour costs and minimizing errors. By combining the strengths of automation with human expertise, warehouses can adapt to changing demands and maintain a competitive edge in the logistics industry.

Bastian Solutions' Approach to Human-Automation Collaboration

Through meticulous assessment of existing workflows and operational goals, our experts can identify opportunities for automation integration. Leveraging advanced technologies such as robotics and AI, we design and implement systems that complement human capabilities. Our solutions are not only technically robust but also user-friendly, ensuring smooth adoption by employees.

With a focus on continuous improvement, our team ensures that automated systems evolve alongside human operations, further optimizing processes over time. By combining cutting-edge technology with a deep understanding of human-centric design principles, we will enable companies to achieve the best automated and optimized processes tailored to their unique needs and objectives.

Mebin is a senior application engineer for the Bastian Solutions sales and application engineering. He has a bachelor's degree in mechanical engineering from the IIE Institution. As an application engineer, he helps Bastian Solutions customers find the right warehouse automation solutions. Which includes conveyor systems, palletizers, and automatic storage and retrieval systems.

Comments

No comments have been posted to this Blog Post

Leave a Reply

Your email address will not be published.

Comment

Thank you for your comment.